- A flexible perovskite module with WVTR ≈ 5.0 × 10⁻³ g/m²/day retained 84% of its power after 2,000 hours at 85°C/85% RH (Damp-Heat).

- Japan is subsidizing Sekisui Chemical to build a 100 MW film-type perovskite plant by 2027 to help reach about 20 GW of capacity by 2040.

- Anker demonstrated a perovskite-powered beach umbrella at CES 2025.

- A flexible perovskite/silicon tandem achieved 29.88% certified efficiency in a small-area research device.

- A Chinese startup unveiled a 1.2 m × 1.6 m flexible module rated 260–300 W and weighing 2.04 kg (≈147 W/kg).

- Several manufacturers have passed IEC 61215/61730 reliability tests (including 3× damp-heat/thermal cycling), signaling progress toward standards for flexible modules.

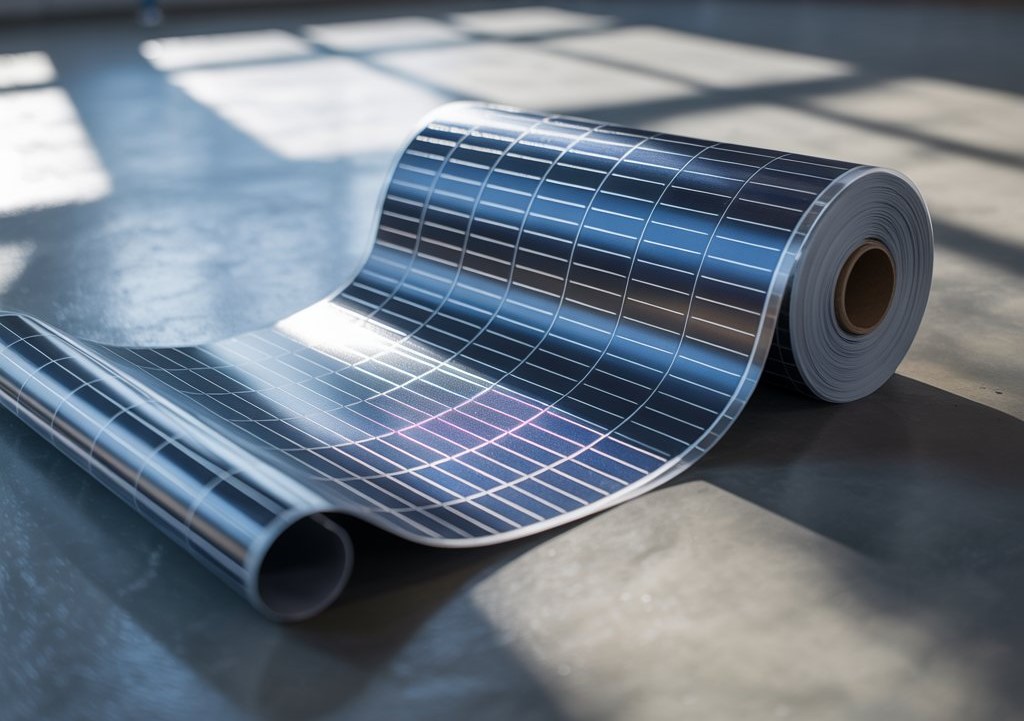

- Roll-to-roll production can fabricate devices at <150°C, with a techno-economic projection of ~$0.7/W at 1,000,000 m²/yr.

- Barrier films and edge-seals are critical; strategies include PIB adhesives and low‑stress lamination to reduce thermal/mechanical damage.

- Lead management efforts include external barrier encapsulants and internal dopants to immobilize Pb, plus end-of-life recycling plans.

- Japan’s building-exterior pilots and Expo 2025 demonstrations point to building skins, curved façades, and portable devices as near-term targets.

Ultra‑thin perovskite photovoltaics laminated onto flexible films are moving from lab to market. Japan is investing big (billions) and early products and pilots are appearing. The promise: lightweight power on curved or weight‑limited surfaces with fast, low‑temperature, roll‑to‑roll manufacturing. The hurdles: durability (moisture/heat), safe lead management, and bankable certification. [1], [2], [3]

What we mean by “photovoltaics from perovskites in flexible laminates”

Perovskites are a class of crystal materials that convert light to electricity very efficiently and can be processed from inks at low temperatures. Flexible laminates package those cells between polymer barrier films and adhesives (instead of heavy glass), creating thin, light solar sheets that can bend and conform to surfaces like façades, membranes, vehicles, tents, and IoT devices. [4] [5] [6]

A typical flexible stack looks like this (front to back):

- transparent polymer substrate (e.g., PET or PI) with a thin conductive layer,

- electron/hole transport layers,

- the perovskite absorber,

- a thin rear electrode (metal, carbon, or transparent conductor),

- encapsulant adhesive (POE/EVA/PIB, etc.),

- ultrabarrier back film (to keep out water/oxygen), plus edge seals. [7], [8]

Why laminates matter: water vapor quickly damages perovskites, so the barrier’s water‑vapor transmission rate (WVTR) and the lamination process determine lifetime. In recent tests, modules using the tightest barrier in the study (WVTR ≈ 5.0 × 10⁻³ g/m²/day) retained 84% of their power after 2,000 h at 85 °C/85% RH (Damp‑Heat). Weaker barriers failed far sooner. [9]

What changed in 2024–2025?

- Japan’s national push. The government is backing flexible perovskites to challenge China’s PV dominance, including major subsidies for Sekisui Chemical to build a 100 MW film‑type perovskite plant by 2027. Japan’s target is ~20 GW of perovskite capacity by 2040. [10], [11], [12]

- First consumer‑adjacent demonstrations. Anker showed a perovskite‑powered beach umbrella at CES 2025 (marketing claims are bold and not independently verified), reflecting how perovskites can power curved, portable gear. [13]

- Flexible efficiency records. Researchers reported 29.88% certified efficiency for a flexible perovskite/silicon monolithic tandem (small area, research device) — a milestone that narrows the gap between flexible and rigid. [14]

- Bigger flexible modules. A Chinese startup introduced a 1.2 m × 1.6 m flexible module rated 260–300 W and just 2.04 kg (~147 W/kg), pointing to high specific power on weight‑limited surfaces. (Vendor claims; early‑stage.) [15]

- Toward bankability. Multiple Chinese makers reported passing IEC 61215/61730 reliability regimes (and even 3× accelerated aging) — mostly for rigid perovskite modules so far, but it signals rapid progress toward standardized durability. [16]

“When you have a technology in its very early stages, you have the ability to design it better.” — Joey Luther, NREL. [17]

How flexible perovskite laminates are made (and why encapsulation is the make‑or‑break)

- Low‑temperature device fabrication

Perovskite layers and contacts can be printed or coated at <150 °C and scaled with roll‑to‑roll tools — the same manufacturing logic used for packaging or battery foils. A 2024 techno‑economic study of all‑R2R perovskites projected ~$0.7/W at 1,000,000 m²/yr with room for further cost declines as lines scale. [18] - Lamination & adhesives

Conventional PV lamination (for glass modules) uses ~150–160 °C for POE/EVA cross‑linking. That temperature can hurt perovskites, so two strategies emerged:- Engineer the cell to survive vacuum lamination at 150 °C (e.g., internal diffusion barriers, ALD SnOₓ), orLower the lamination stress/temperature with viscoelastic PIB‑based adhesives or room‑temperature/low‑pressure approaches, reducing thermal/mechanical shock. [19], [20], [21]

- Barrier films & edge‑seals

Moisture is the dominant failure mode. Beyond high‑quality barrier films (often multilayer inorganic/organic stacks), edge‑sealants (e.g., butyl) and adhesive chemistries are tuned to block water and immobilize lead if damage occurs. Multiple reviews and studies in 2024–2025 catalog strong encapsulant candidates and lead‑sequestration strategies. [23], [24], [25]

“Perovskite solar cells… offer unique opportunities… However, the stability… is weak compared with conventional material, which can be improved by… encapsulation with barrier films.” — Prof. Takashi Minemoto, Ritsumeikan Univ. [26]

Performance snapshot (2025)

- Lab‑scale flexible tandems:29.88% certified (perovskite/silicon, small area). [27]

- Commercializing single‑junction modules: Reported flexible modules 260–300 W at 2.04 kg; others report 18.1% module efficiency (rigid) verified by NREL — indicating fast module‑level gains. [28]

- Mechanical durability: Flexible cells retaining ~96% efficiency after 10,000 bends at 5 mm radius were reported in 2024 research; tandems with thin Si have kept performance after 2,000 bend cycles. (Test setups vary.) [29] [30]

“We introduced the concept of composite materials into the interface design… achieving results unattainable with traditional interface engineering.” — Dr. Guo Pengfei, HKUST. [31]

Where flexible laminates fit best

- Building skins / membranes—weight‑limited roofs, curved façades, temporary structures. Japan has piloted film‑type perovskites on building exteriors, and Expo 2025 showcases perovskite films in public spaces. [32], [33]

- Vehicles & mobility—curved surfaces (roofs, fairings), trailers, and drones benefit from high W/kg and conformability. [34]

- Portable & IoT—umbrellas, tents, signage and low‑power devices, where low‑light response and form factor matter more than absolute $/W. [35]

Safety & sustainability: the lead question (and real solutions)

Most high‑performance perovskites use a small amount of lead. Risk comes if a module is broken and soaked. Mitigations include:

- External: tight barrier films + robust edge seals + lead‑binding encapsulants to immobilize Pb if the laminate is damaged.

- Internal: dopants and additives that sequester Pb inside the perovskite microstructure; designs that facilitate recycling at end‑of‑life. [36], [37], [38]

Recent research shows lamination chemistries and sequestration layers can cut lead leakage by orders of magnitude; reviews in 2025 summarize viable materials (polymers, resins, nanoparticles) and circularity pathways. [39], [40]

Bankability & standards: what “good” will look like

- Module tests: Passing IEC 61215/61730 is the baseline for outdoor PV. In 2025, manufacturers reported certifications (largely rigid perovskites), including triple‑strength aging (3× damp‑heat/thermal‑cycling), a strong signpost for durability. Flexible modules must meet similar or adapted criteria as standards evolve. [41]

- Manufacturing compatibility: Standard vacuum lamination at ~150 °C stresses perovskites — so either use lamination‑tolerant device stacks or low‑stress adhesives/presses. [42] [43]

- Barrier performance: Controlled studies tie WVTR directly to damp‑heat survival; choose ultra‑low‑WVTR films and proven edge‑seals. [44]

Costs & economics (early but encouraging)

- Emerging R2R lines (ink/slot‑die, blade, PVD/ALD for contacts) could reach ~$0.7/W at scale, with further learning‑curve driven reductions. LCOE depends most on efficiency and lifetime; analyses suggest perovskites become compelling as modules cross ~20–24% and last 15–25+ years, especially in lightweight/flexible niches with BOS savings. [45] [46]

The fine print: realities from the last two years

- Hype vs. hardening: Alongside genuine progress, some high‑profile flexible pioneers struggled financially (e.g., Saule Technologies reported severe distress in 2025). Treat flashy demos and marketing specs with due diligence. [47] [48]

- Claims need third‑party data: Early consumer devices (like the perovskite umbrella) cite striking efficiencies, but independent verification is rare. Ask for certified test reports. [49]

How to evaluate a flexible perovskite laminate today

Ask vendors for:

- Certification proofs: IEC 61215/61730 (or equivalent) test reports for the exact product revision. [50]

- Barrier specs: WVTR/OTR values of the laminate and edge‑seal system; damp‑heat (85 °C/85% RH) and UV test results. [51]

- Thermal process window: Lamination temperature/time and evidence the device survives the process (e.g., pre/post‑lamination PCE, EL images). [52]

- Mechanical data: Bend radius and cycles at which ≥90–95% performance is retained. [53]

- Lead management: Encapsulant chemistry and lead‑capture measures; EHS documentation and end‑of‑life recycling plan. [54] [55]

- Warranty & field pilots: Locations, durations, and monitored performance of real installations (ideally 12–24 months+).

Expert quotes you can use

- NREL (sustainability first): “Pushing perovskite PV toward enhanced sustainability makes more sense at this stage.” — Joey Luther. [56]

- Ritsumeikan Univ. (barriers matter): “Stability… can be improved by… encapsulation with barrier films.” — Takashi Minemoto. [57]

- HKUST (interfaces by design): “We introduced the concept of composite materials into the interface design…” — Guo Pengfei. [58]

Outlook: what to watch next

- Scale‑up of film‑type lines (e.g., Sekisui’s 100 MW by 2027) and how yields evolve on R2R production. [59]

- Bankable lifetimes: More third‑party IEC passes (including for flexible products), longer outdoor datasets, and warranties ≥10–15 years. [60]

- Safer stacks: Wider adoption of lead‑sequestering adhesives/films and recycling logistics at end‑of‑life. [61]

- Hybrid architectures: Thin‑silicon + perovskite tandems on flexible carriers for higher efficiency without sacrificing bendability. [62]

Current headlines & key reporting (updated to August 15, 2025)

- Japan’s $1.5 billion bet on ultra‑thin flexible perovskites (policy + industry build‑out). [63]

- Qcells reports large‑area perovskite‑on‑silicon cell advance (relevant to tandems/future laminates). [64]

- Anker’s perovskite umbrella signals consumer experimentation (specs unverified). [65]

Fresh coverage: perovskite PV & flexible laminates (2025) [66] [67]

Further reading (selected research & analysis)

- Roll‑to‑roll manufacturing & cost: Nature Communications (2024) projecting ~$0.7/W at scale. [68]

- Lamination innovations: Low‑stress PIB adhesives (2024) and isostatic press lamination (2024). [69]

- Barrier film evidence: Damp‑heat study tying WVTR to survival (2025). [70]

- Flexible tandem milestone: 29.88% certified (2025). [71]

- Industry roll‑out: 2025 progress snapshots and module gains. [72]

Bottom line

Flexible perovskite laminates are not a science‑fiction idea anymore. With serious national funding, visible pilots, and fast‑improving encapsulation science, they’re on track to serve the lightweight, conformal niches where glass modules can’t go — and to do so at compelling economics if durability targets are met. Keep a sharp eye on barrier quality, lamination stress, and independent certifications when you see the next “solar sticker” headline. [73], [74], [75]

References

1. www.ft.com, 2. www.sciencedirect.com, 3. www.nature.com, 4. www.sciencedirect.com, 5. pubs.acs.org, 6. pubs.acs.org, 7. images.assettype.com, 8. link.aps.org, 9. en.ritsumei.ac.jp, 10. www.ft.com, 11. www.pv-tech.org, 12. techxplore.com, 13. www.theverge.com, 14. www.nature.com, 15. www.pv-magazine.com, 16. www.perovskite-info.com, 17. www.nrel.gov, 18. www.nature.com, 19. research-hub.nrel.gov, 20. www.nature.com, 21. images.assettype.com, 22. www.nature.com, 23. pubs.acs.org, 24. pubs.aip.org, 25. pubs.rsc.org, 26. en.ritsumei.ac.jp, 27. www.nature.com, 28. www.pv-magazine.com, 29. www.azocleantech.com, 30. www.nature.com, 31. techxplore.com, 32. www.sekisuichemical.com, 33. advanced.onlinelibrary.wiley.com, 34. automotive.messefrankfurt.com, 35. www.theverge.com, 36. pubs.aip.org, 37. pubs.acs.org, 38. www.nature.com, 39. onlinelibrary.wiley.com, 40. www.sciencedirect.com, 41. www.perovskite-info.com, 42. research-hub.nrel.gov, 43. www.nature.com, 44. en.ritsumei.ac.jp, 45. www.nature.com, 46. pubs.rsc.org, 47. www.perovskite-info.com, 48. www.pvtime.org, 49. www.theverge.com, 50. couleenergy.com, 51. en.ritsumei.ac.jp, 52. research-hub.nrel.gov, 53. www.azocleantech.com, 54. pubs.aip.org, 55. www.nature.com, 56. www.nrel.gov, 57. en.ritsumei.ac.jp, 58. techxplore.com, 59. www.pv-tech.org, 60. www.perovskite-info.com, 61. pubs.aip.org, 62. www.nature.com, 63. www.ft.com, 64. www.reuters.com, 65. www.theverge.com, 66. www.ft.com, 67. www.reuters.com, 68. www.nature.com, 69. www.nature.com, 70. en.ritsumei.ac.jp, 71. www.nature.com, 72. www.pv-magazine.com, 73. www.ft.com, 74. research-hub.nrel.gov, 75. www.perovskite-info.com